Harman ultrasonic metal spot welder

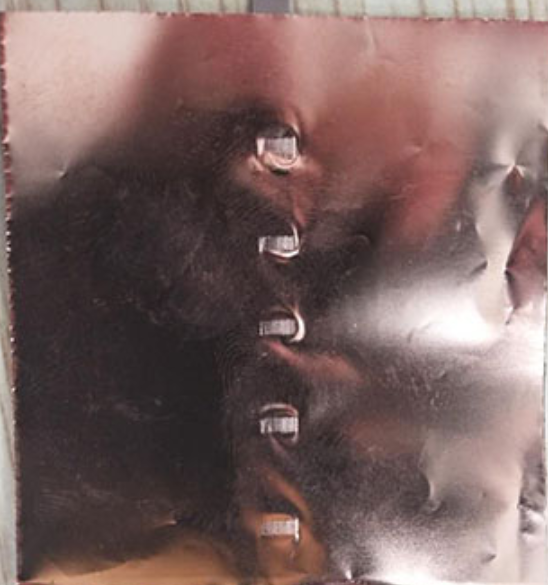

The wires are interfused with various electronic components, contacts and connectors

-Microcomputer control, electronic tuning frequency,LCD display, power continuously adjustable, simple operation, stable and reliable operation

-the welding material is not molten, not fragile metal characteristics

-Good electrical conductivity after welding, very low or almost zero resistivity

-Low requirements for welding metal surface, oxidation or electroplating can be welded

- Details

- Parameter

Characteristics of ultrasonic metal welding

1、No flux and external heating, no deformation due to heat, no residual stress, the surface of welding parts of the pre-welding treatment requirements are not high.

2、Not only similar metals, but also different metals can be welded

3、Thin plates or filaments can be welded onto thick plates

4、Ultrasonic welding has much less energy than electric current welding. It is often used to weld leads of transistors or integrated circuits

5、When used for sealing welding of drugs and explosive materials, it can avoid contamination of drugs due to dissolved objects in general welding, and won't explode due to being heated

6、Short welding time, do not need any flux, gas, solder

7、No skilled workers are required, and only one day of training is required to use the equipment